- Home

- Textile Machinery

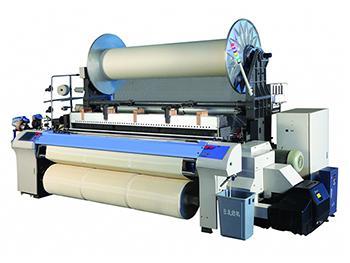

- Water Jet Loom

Water Jet Loom

The RFJW series water jet loom uses a virtual prototype for weft insertion design, shedding and beating up, so that the loom's vibration rate is 25% less than similar products under the same weaving conditions, and an energy consumption that is 5% lower.

This water jet loom is suitable for weft insertion of spun yarn with a smooth surface and fiberglass or other filaments. It improves the conductivity of the spun yarn, thus preventing any static electricity during the weaving process. A spray weft yarn also requires less energy and produces less noise during production.

Nominal reed width: 150, 170, 190, 210, 230cm

Effective reed width: nominal reed width (0-50cm)

Weft selection: 2 color free weft selection

Power of the motor: 2.7KW, 3.0KW, 3.7KW

- Extensive functions: the high speed water jet loom uses a ceramic nozzle to improve the weft insertion stability under the loom's high speed weaving performance.

- Convenient operation: the loom features a comfortable, easy operation. Operator comfort is improved by the position height of the warp end, and the use of an HD, colorful touch screen with an easy to use human to machine interface ensures all basic functions are easily carried out.

- Environmentally friendly: The RFJW10 water jet loom features a virtual prototype to improve the structure and reduce the vibration rate by 25%, when compared to other similar products on the market today. This also lowers the energy consumption by 5%.

- Solid and tough machine rack: the machine rack is a complete structure, meaning the let off plate is a single piece made through side plate forging. The box wall panel and strengthened beam form a solid machine rack. This structure effectively protects the machine from ground vibration and running noise, ensuring the loom is stable during high speed operation.

- Automatic cloth-fell aiming: when the loom is repaired after coming to a stop, it will carry out an automatic cloth fell after restarting. This makes operation easier, and improves the working efficiency.

- Direct drive motor: this unit is used to prevent stops and loosening of the weft yarn's first pick during the loom start up. By using a large capacity electromagnetic brake directly connected to the crank shaft, this machine achieves an accurate stop at certain position.

- CC spindle: this unit effectively prevents weft shaking during high speed loom operation, thus reducing mistakes in the weft pick finding.

- Vibration Permanent Magnetism electric drum accumulator: this device features a high speed tracking performance. It is also equipped with a yarn separation device from the yarn layers. This means that weft accumulating and releasing from fine yarn to coarse yarn is simple and stable.

- A new ceramic nozzle further improves the clustering performance of the water spraying so that the loom can run in a stable manner with a relatively small shedding and water quantity.

- A new high performance water pump improves the clustering performance of the water spraying to improve the weft insertion capability. In order to adapt to weaving of different fabrics, you can choose either a single suction water pump or double suction water pump.

- Beating up balance system: it uses an eccentric rock shaft with an extra small inertia torque to achieve a balanced beating up under high speed running. By being equipped with the solid rack structure, the ground vibration will be reduced by 25%, which also ensures a more stable high speed operation.

- Let off system: the strengthened double let off roller is not only suitable for weaving of both light and heavy fabrics, it can also improve the fabric weaving quality.

- The HD colorful touch screen human computer interface: the user can easily set working parameters for the loom and accumulator, and allows users to choose specific functions, such as production statement analysis, checking and alarming and more. This system also features a wireless user card that offers different levels of authority to different users.

- Electronic control system: this water jet loom uses an advanced electronic control system with an outstanding circuit board, high integration level, good anti-interference performance, wide working environment and stable operation, thus ensuring a safe production and excellent fabric quality.

| Item | Specification | |

| Power mechanism | Starting method | Driven by super start motor |

| Running operation | Direct stop location control carried out by electromagnetic brake | |

| Button operation (preparing, running, stop, normal inching turning, reverse inching turning, reverse a round to stop at certain position) | ||

| APF-W automatic cloth-fell aiming | ||

| Beating mechanism | Crank type beating, multiple sley sword beating, bath oil type | |

| Weft insertion mechanism | Pump | Plunger type Spring-loaded system |

| Nozzle | Ring nozzle voltage stabilizer (ceramic needle) | |

| Measuring accumulator | Vibration Permanent Magnetism electric drum accumulator (2 colors) | |

| Shedding mechanism | Crank shedding motion: 4 heald frames, 6 heald frames | |

| Cam shedding motion: upper positive cam: 10 heald frames | ||

| Dobby shedding motion: upper negative 16 frames, upper positive dobby: 16 heald frames | ||

| Jacquard shedding motion | ||

| Let off mechanism | ELO electronic let off, PSS-W stop mark to prevent losing control | |

| Max tension | 2300N, 4000N | |

| Back rest | Standard | |

| Flange diameter | 800mm (optional 914mm, 1000mm, 1100mm) | |

| Take-up mechanism | Take up method | ETU electronic take up |

| Cloth coller length | 520mm | |

| Cloth roll pathway | S roll incline before weaving, S roll | |

| Yarn supply frame | Floor stand lateral 4 yarn cone (2 color) | |

| Selvage mechanism | Planetary gear type | |

| Yarn end treatment | Spindle false twisting | |

| Weft cutter | Mechanical weft cutter | |

| Temple | Upper temple shafts with double rings | |

| Dehydration method | Microslit tube suction method (high pressure fan 400W) | |

| Stop motion | Weft break | OPF photoelectric weft feeler |

| Cause of stop motion display | Navi keyboard information display | |

| Multifunctional 4 color stop motion display | ||

| Automatic function | Navi keyboard | Automatic parameter setting, recommended value display and best running condition guide |

| Automatic control, trouble removal and self diagnosis | ||

| Running information and maintenance information display | ||

| Internet | Centralized networking and loom monitoring system | |

Shandong Rifa Textile Machinery Co., Ltd.

Contact Person: Mr Zhao Zongfa

Tel.: +86-635-2999585

Fax: +86-635-8516735